Today, Mia will take you to know more details about the cosmetic tubes extrusion line in Auber Packaging factory.

Let's follow the camera and check the tube extruding.

This video will show you how Auber extrude the cosmetic tubes. The material will be pumped into the machine, heated and extruded into the cylinder shape, and then cut into the specific length. As one of the custom cosmetic packaging, Auber can make the tube packaging in any size, any length and any color you want. Talk to us if you had any question. Auber will provide the packaging solutions with the 18 yrs experience.

The raw materials will be pumped into the machine.

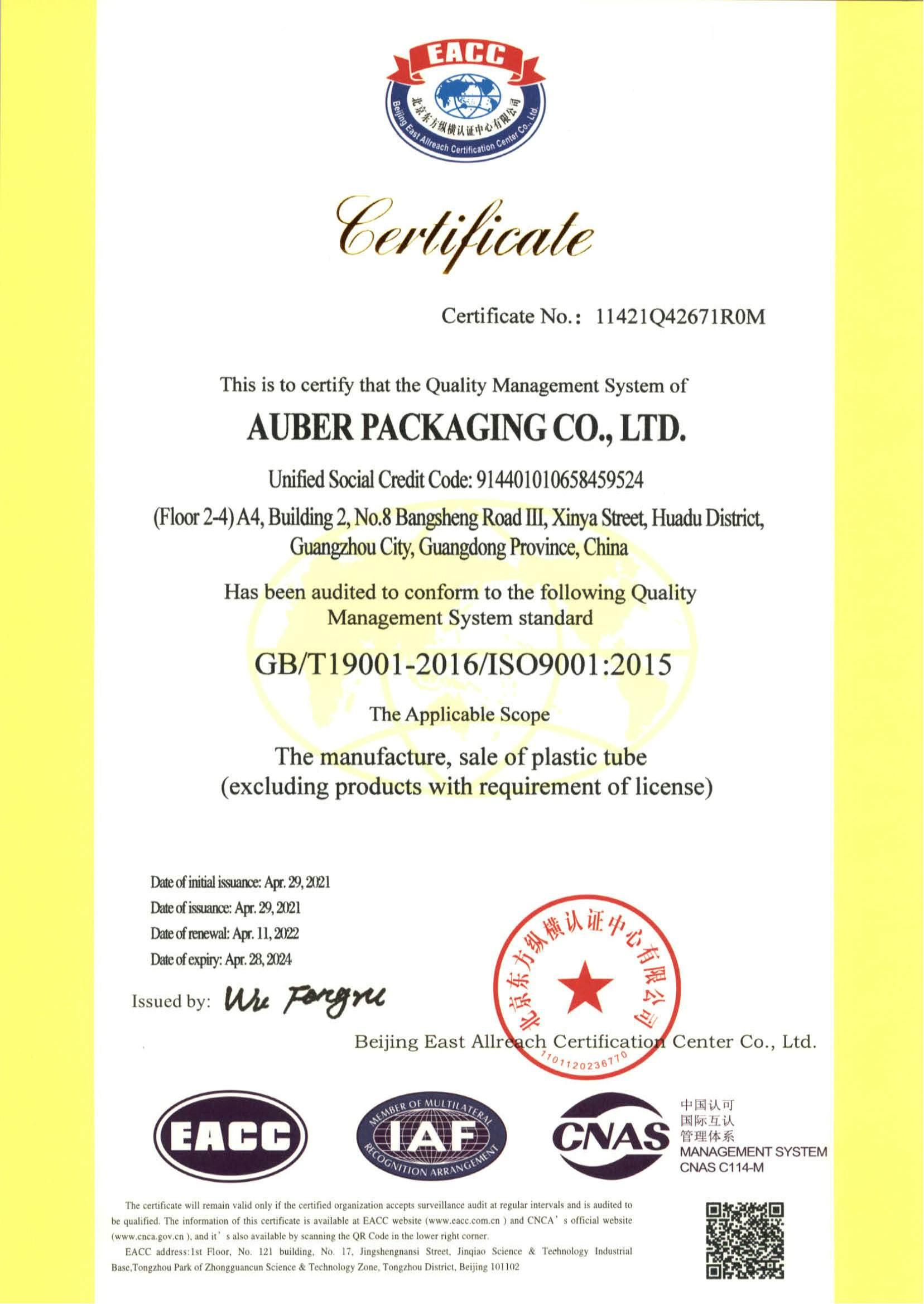

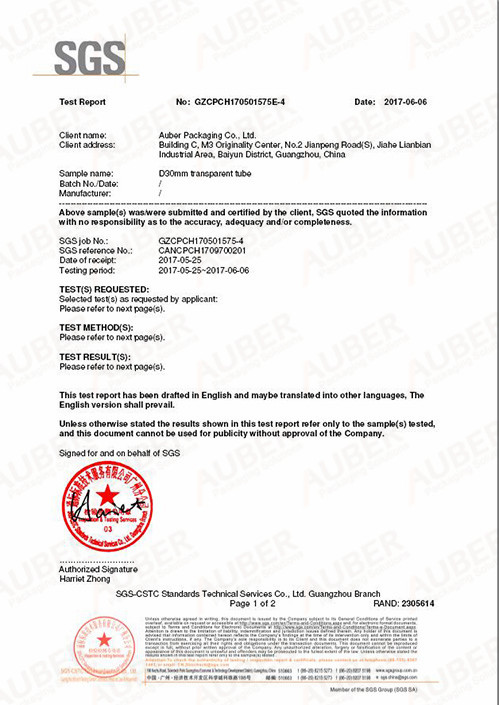

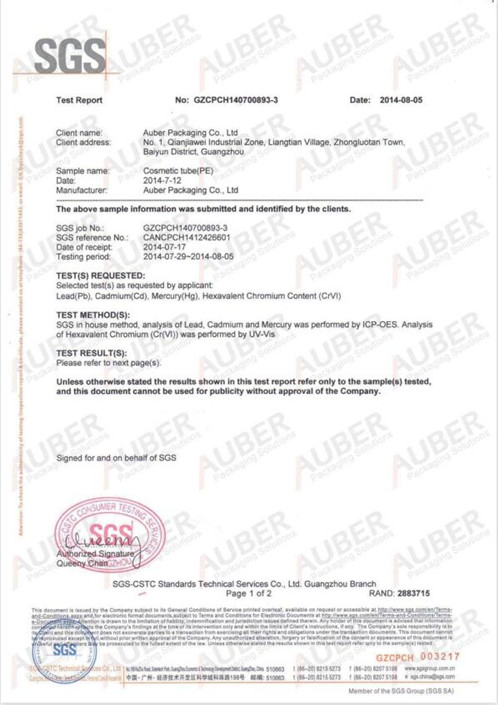

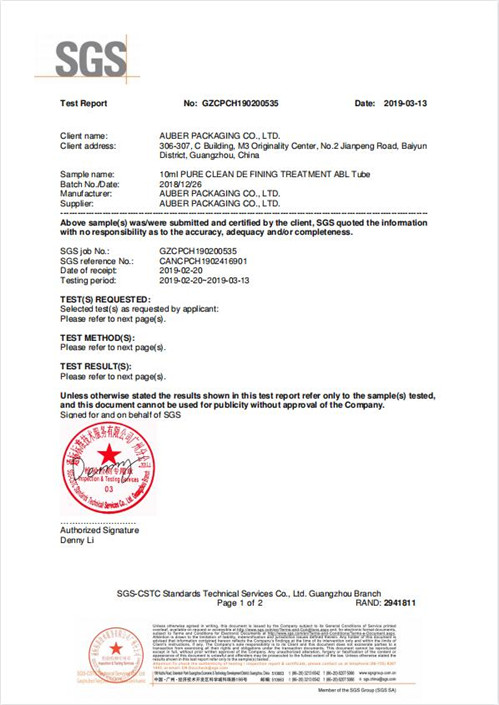

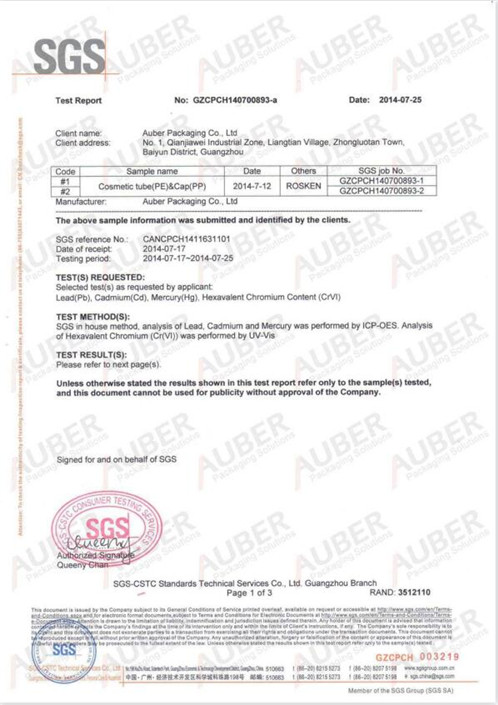

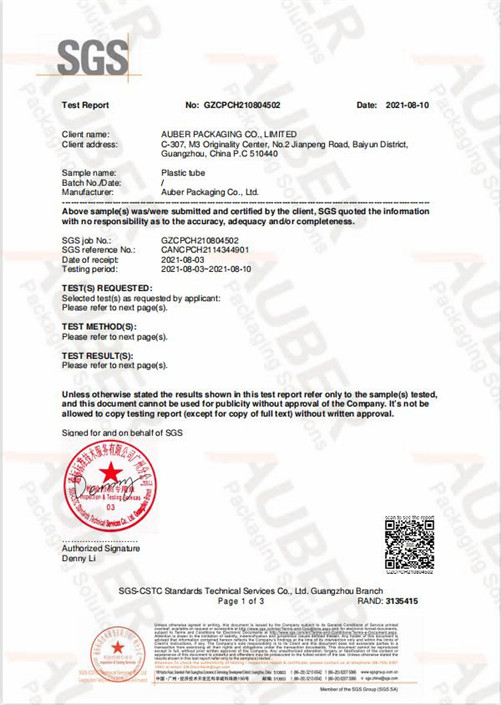

Auber is an ISO9001 Certified manufacturer since 2004.

We are specialized in producing plastic cosmetic tubes & metal cosmetic tubes in wide range:

♦ PE tubes: Mono-layer, Double-layer and Multi-layer(5 layers)

Laminated tubes: ABL (Aluminum plastic laminated tubes), PBL (Plastic laminated tubes), HGL (High glossy laminated tubes)

♦ Diameters: from 13mm to 60mm

♦ Different decorations: offset printing, silkscreen printing, hot stamping, labeling, etc

♦ We offer private label and contract packaging services

♦ Our tubes are used in cosmetics, skincare, hair care, pharmaceutical, food, chemicals, medicine, painting, industrial use, etc.

We are focusing on quality control by strictly following the ISO9001:2015 standard.

We consider loyalty and customer service as the priority on business relationship. The high satisfaction from our customers has helped us explored the markets into North America, Europe, Australia, Japan, Mid-East, etc.

Start to customize the cosmetic tube packaging

We consider loyalty and customer service as the priority on business relationship. The high satisfaction from our customers has helped us explored the markets into North America, Europe, Australia, Japan, Mid-East, etc.

Copyright © 2022 Auber Packaging Co., Ltd. - All Rights Reserved.